A sewing machine is a device used to stitch clothes, with the help of a needle and a shuttle that holds the thread. It is used to stitch clothes or leather and is powered by electricity, treadle, or waterpower.

It is a widely distributed mechanical device and is a huge industrial appliance or machine. It was first invented during the industrial revolution to help and boost the sewing work performed by hand in clothing companies. The sewing machine was invented by Thomas Saint in 1790.

History and Importance of Sewing Machines

Thomas Saint, in 1790, created the first design of a sewing machine. He designed his machine to be used on leather, and canvas materials. His sewing machine consisted of a single thread to make normal and easy stitches in the fabric. The fabric was pierced by a stitching awl and a pointed rod would take the thread through the hole.

His mechanism was then founded by William Newton Wilson, a sewing machine manufacturer in 1874 at the UK Patent Office, who made some adjustments to the looper, and this mechanism is currently owned by the Science Museum of London.

For stitching purposes, Englishmen Thomas Stone and James Henderson made a sewing machine in 1804. John Duncan from Scotland built a sewing machine for embroidering purposes. Josef Medersperger, an Australian tailor, started to develop his sewing machine in 1807 and showed his first working sewing machine in 1814.

He worked on the development of machines till 1839 after receiving financial support from the Australian government. He built his machine, which imitated the weaving process, which used the chain stitch. Then many other inventors worked on the development of sewing machines.

The English inventor John Fisher 1844, built the first sewing machine, which combined the disparate elements of all the old half-century of innovation in his modern sewing machine. But his modern sewing machine did not receive recognition for some of the disputes in legal matters.

From this invention, several other inventors got the idea and modified the sewing machines to work more efficiently. Many designs were made by many inventors, but the present type of design, which is now available most in the market, is the easiest to use and most efficient design of sewing machines.

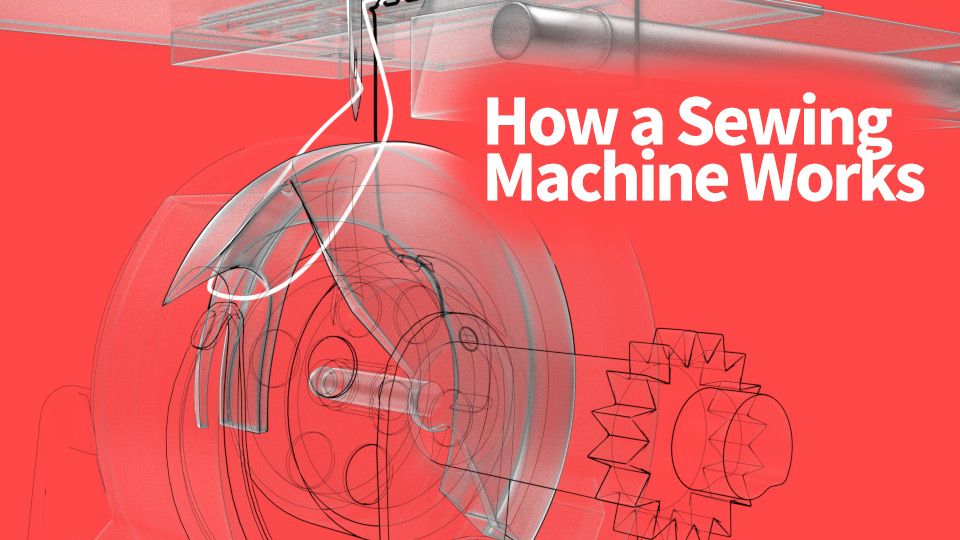

How Does a Sewing Machine Work?

Without a sewing machine, people would not have any variety of fancy clothes or any type of decorative and cheap clothes. A sewing machine is a compact device where many moving parts are packed in a small place.

- The needle rises and goes down on the fabric.

- The needle tears or punctures the fabric along with the thread with it.

- The thread is tied at both sides so it does not rip open.

- The needle then again goes up, leaving back a loop of the thread.

- From here, the next stitching begins. The shuttle hook passes through the loop and catches in it. You will find the needle rising on the upper side, but the main work is done at the bottom of the material.

- At the bottom, the shuttle hook drags the thread loop right around it, locking the bobbin thread.

- The needle, when pulled upwards, tightens the thread pulling it back up off the shuttle hook.

When the needle pulls the thread and makes the stitching tight and strong. The threads are properly locked together and repeat the process to complete your stitching.

In the manually powered sewing machine, a foot paddle is attached through which you can increase your speed of stitching. The paddle increased the speed of the needle going up and down through the material.

Home Sewing Machines – A Detailed Infomatics

These are designed for workers who used to sew clothes in their homes. They are small and efficient, easy to use. These sewing machines are used for a single person to sew items with a single stitch type at a time. Early sewing machines are manually powered.

They are turned with a handle or with a foot-operated treadle to turn the needle. Electricity-powered or modern sewing machines were later invented. Modern-style sewing machines are powered by electricity and operate automatically.

In this mechanism, the fabric goes in and comes out of the machine without the inconvenience of the needle, thimbles, and other tools used in a sewing machine.

How To Use a Home Sewing Machine?

To use a home sewing machine, these are the simple steps you should follow.

- Depending on the size and type of your home sewing machine, you have to raise the needle with the help of a button or a knob.

- Under the needle, you have to place the fabric to make the first line of the stitches, and to keep the fabric in place while sewing keeps the presser foot low.

- The foot pedal controls the speed of the needle so, pressing the foot pedal will make the needle start stitching. To increase the speed of the needle press the pedal harder, and slowly decrease the speed of the needle.

- To keep the stitches unraveling, lock the stickers at the starting or ending of a seam. For this mechanism sew a few stitches at the front of the fabric and then sew on the reverse side. In electronic sewing machines, they have the button to sew on the reverse side written as the Lock Stitch button.

- If you want to stitch in a straight line then keep the fabric’s edge lined up with a scale or seam. The machine will automatically start stitching by pulling the fabric, no need to push the fabric also.

- To make your stitch compact and tight, lock the ending stitches, or reverse sew the last stitches. You can do it with your hand or with the reverse sewing button present on the machine.

- After this detach your fabric from the needle and press your foot by raising them up.

- After all the steps are done pull your fabric out from the sewing machine. Cut the extra thread with scissors. There are some sewing machines that have an inbuilt cutter to cut the extra thread.

Industrial Sewing Machines

Industrial sewing machines are much bigger in size as compared to home sewing machines. They are more powerful and, faster, and vary in cost, size, appearance, and work.

How to use an industrial sewing machine?

Industrial sewing machines are used in the production of vast amounts of garments. It is generally powered and works at a very high speed. There are many types of industrial sewing machines that are developed for different types of purposes.

Lock stitch, chain stitch, cover stitch, and overlock are the main types of stitches used in an industrial sewing machine. As mentioned earlier their work remains the same in an industrial sewing machine. The other types are –

- Single needle lock stitch machine – These machines are used to make lock stitches. This is a widely used industrial sewing machine. They are used to join more than one fabric plies together. It is used to sew lightweight, medium, and heavy materials. Its computer-controlled version is also available.

- Overlock sewing machine – These machines are available in 3, 4, and 5-thread over-edge sewing. They are basically used for serging garment panels and for overedge stitch. Ex – trouser panel serging, side seam stitch on a t-shirt. These are done on an overlock sewing machine.

- Flatlock sewing machine – It is also called a cover stitch sewing machine. They come with 2-3 needles. 2 needles pass through the fabric for the bottom cover stitch and the 1 forms the inter loop on the bottom side of the seam.

- The feed of the arm – These are used to make flat and felt seams. They are used to stitch shirt side seams, jeans inseam, and underarms.

- Button-attaching sewing machine – These sewing machines are used to attach buttons to garments. You can attach different types and sizes of buttons by changing the settings.

- Buttonhole sewing machine – These machines are used to make buttonholes on garments. In this machine also you can change the type and sizes of buttonholes by changing the settings.

- Bartack sewing machine – These machines are used to reinforce the garment component and the seam. Ex- The pocket openings are generally done by bartacking.

- Zigzag sewing machine – The sewing machines are used to make zigzag stitches. Ex – Jacket manufacturing, etc.

- Multi-needle chain stitch – These machines are used to tuck pins on garments and for smoking operations.

- Double needle lock stitch sewing machine – The machines are used to stitch two stitch lines on a garment at a time. In a double needle lock stitch sewing machine, the sewing is done very fast and easily.

Design of Sewing Machines

In a sewing machine, you can make many different types of plain or patterned stitches. The ISO has recognized over three dozen distinct stitch formations.

There are 4 types of plain stitches which are lockstitch, chain stitch, cover stitch, and overlock.

Lockstitch

It is a type of stitch method commonly used by most household sewing machines and industrial single-needle sewing machines. It uses two threads, one thread passes through the needle, and the other thread comes from the shuttle.

The thread stays on the same side of the sewing material, it interlaces with the other thread at each needle hole with the help of a bobbin driver. Thus, a lockstitch does not need to be near the edge of the sewing material and be formed anywhere on the material.

Chain stitch

This method was used in the early sewing machines. It has two major disadvantages. They are –

- If the thread tears at any point or is not properly tied at both ends, the full stitching comes out, as it is not self-locking, so it easily gets ripped out.

- You cannot change the direction of your stitching otherwise, the stitching process will fail.

Coverstitch

It comprises more than one needle and more than one looper. It can be formed anywhere on the material being sewn. One looper controls the thread below the sewn material which firms a bottom cover stitch simultaneously. In this mechanism the needle thread firms parallel rows and the looper threads cross each other at all the needle rows. This mechanism is mainly used in garment manufacturing.

Overlock

It is also known as ” server stitch ” or ” serging “. In this sewing machine, a knife is attached to trim the edges immediately when the stitch is performed. Industrial and garment overlock machines are vastly used in garment seams in knit, stretchable fabrics. The overlock machine with more than five threads makes a chain stitch with a needle and a looper. The remaining needles and loopers form the overlock stitch. This combination is widely known as Safety Stitch.

Conclusion

Before the invention of the sewing machines, women had to hand-knit clothes. The poor women and workers had to give enough time to complete the stitching by hand knitting. An experienced worker needed 14 hours to complete knitting a shirt for a man, 10 hours to knit a women’s dress, and about 3 hours to knit a pair of trousers.

The invention of sewing machines reduced the time of knitting and stitching. This invention also reduced labor, and women could concentrate more on their families and household. The use of sewing machines in industries also reduced the burden placed on women and workers.

Through sewing machines, garments were manufactured abundantly, making growth in industries and factories. This resulted in large-scale production, and the prices of clothes dropped due to plenty of its availability.

With the increase in garment industries, there was also an increase in the availability of its materials. This resulted in the increase of more factories which provided work to many people. Apart from clothing, sewing machines are also important in manufacturing curtains, towels, soft toys, books, and many other products related to stitching.

I love sewing, I am sewing for the last 15 years and started this blog with the help of my niece to spread sewing-related guides all over the world.

Sewing could be a full-time profession or hobby, and I wish to make a change by adding more people to the sewing world.